Plastic Recycling Machinery

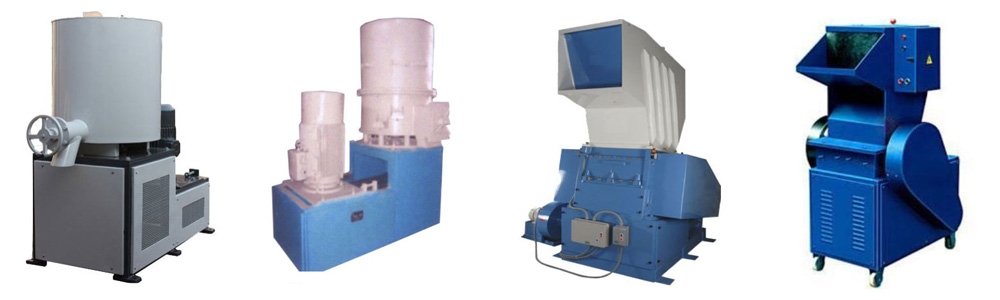

We offer a wide range of Plastic Recycling Machinery as below

- State of art Size Reduction (Grinding) Machines us applicationz we have wide range of size reduction equipments commonly known as Grinders made specially for following applications.

- For Lumps and articles in various size and capacities.

- For hollow article grinder for drums and chairs etc

- For PVC/HDPE pipes

- Hopped Feed/Screw Force Feeder Grinder for PET Bottles which can be used for WET/DRY cutting

- High performance Grinders / Cutters for Fibrous waste (Polyester / Nylon fibre)

.jpg)

General Purpose Grinders(CG-Series)

These conventional design heavy duty grinders have proven track record of versatility and performance and are mostly suitable for:

- Lumps,

- Small plastic articles,

- Small Injection Molding waste

| Model | Rotor dia x Length |

Rotor rows/ Blades | Fix Bed rows/ Blades | Chamber Mouth size | Output Kg/ Hr. | Power HP |

|---|---|---|---|---|---|---|

| CG-12/12 | 200x300 | 3/3 | 2/2 | 300x300 | 50-80 | 10 |

| CG-18/18 | 260x450 | 3/3 | 2/2 | 450x450 | 100-150 | 15 |

| CG-24/24 | 320x600 | 3/3 | 2/2 | 600x600 | 200-250 | 25 |

General Purpose Grinders (AG-Series)

Description:

Our AG series general purpose grinders have following salient features.

Heavy duty welded/machined steel construction Cross cut body design maximizes rotor dia and output for same chamber size compared to horizontal cut body grinders. It also provides easy access in side chamber for ease of blade change and maintenance.

Outboard mounted Plummer- block heavy duty spherical roller bearings with K-type sleeve to prevent contaminations entering the bearings, and K-sleeve makes it easy to remove bearings for easy maintenance.

Rotor and bed knives are adjusted from outside of the granulator in the Precise Fixture/Jig. Constant cutting circle due to adjustable knives.

Application:

Almost all type of plastic waste can be grinded in this type of machine.

Lumps ,Small plastic articles, Small Injection Molding waste, Films, Raffia, Low thickness Pipes etc.

| Model | Rotor dia x Length |

Rotor rows / Blades | Fix Bed rows / Blades | Chamber size | Output Kg / Hr. |

Power HP |

|---|---|---|---|---|---|---|

| AG-12/12 | 220 x 300 | 3/3 | 2/2 | 300 x 300 | 75- 100 | 15 |

| AG-18/18 | 320 x 450 | 3/3 | 2/2 | 450 x 450 | 150- 200 | 25 |

| AG-24/24 | 420 x 600 | 3/3 | 2/2 | 600 x 600 | 250- 300 | 40 |

| AG-24/40 | 420 x 1000 | 3/3 | 2/2 | 600 x 1000 | 400- 450 | 60 |

| AG-30/30 | 520 x 750 | 3/3 | 2/2 | 750 x 750 | 450- 500 | 60 |

| AG-30/48 | 520 x 1200 | 3/3 | 2/2 | 750 x 1200 | 650- 750 | 90 |

.jpg)

Hollow article Grinders (HG-Series)

Our HG series general purpose grinders have following salient features. Heavy duty welded/machined steel construction Cross cut body design maximizes rotor dia and output for same chamber size compared to horizontal cut body grinders. It also provides easy access in side chamber for ease of blade change and maintenance.

Outboard mounted Plummer- block heavy duty spherical roller bearings with K-type sleeve to prevent contaminations entering the bearings, and K-sleeve makes it easy to remove bearings for easy maintenance.

Big hopper and feed mouth to facilitate feeding of big articles.

Rotor and bed knives are adjusted from outside of the granulator in the Precise Fixture/Jig.

Constant cutting circle due to adjustable knives

Application:

Specially designed for bulky hollow articles of plastic like Drums, Chairs, tables, and similar products.

| Model | Rotor dia x Length |

Rotor rows / Blades |

Fix Bed rows / Blades | Chamber size | Output Kg / Hr |

Power HP |

|---|---|---|---|---|---|---|

| HG-24/24 | 420x 600 | 2/2 | 3/3 | 600x 600 | 150- 200 | 40 |

| HG-24/48 | 420x 1200 | 2/2 | 3/3 | 600x 1200 | 300- 400 | 75 |

| HG-30/30 | 520x 750 | 2/2 | 3/3 | 750x 750 | 250- 300 | 60 |

| HG-30/60 | 520x 1500 | 2/2 | 3/3 | 750x 1500 | 500- 600 | 120 |

| HG-40/40 | 650x 1000 | 3/3 | 3/3 | 1000x 1000 | 350- 400 | 90 |

| HG-40/60 | 650x 1500 | 3/3 | 3/3 | 1000x 1500 | 700- 800 | 175 |

.jpg)

Pipe grinders (PG-Series)

Our PG series general purpose grinders have following salient features.

Heavy duty welded/machined steel construction.

Cross cut body design maximizes rotor dia and output for same chamber size compared to horizontal cut body grinders. It also provides easy access in side chamber for ease of blade change and maintenance.

Outboard mounted Plummer- block heavy duty spherical roller bearings with K-type sleeve to prevent contaminations entering the bearings, and K-sleeve makes it easy to remove bearings for easy maintenance

Special design Inclined feed duct attached to grinding chamber.

Rotor and bed knives are adjusted from outside of the granulator in the Precise Fixture/Jig.

Constant cutting circle due to adjustable knives.

Application:

Specially designed for PP, HD, PVC Pipes

| Model | Rotor dia | Rotor rows / Blades | Fix Bed rows / Blades | Chamber size | Output Kg / Hr. |

Power HP |

|---|---|---|---|---|---|---|

| PG-18 / 18 | 320 x 450 | 3 / 3 | 2 / 2 | 450 x 450 | 75 - 100 | 25 |

| PG - 24 / 24 | 420 x 600 | 5 / 5 | 2 / 2 | 600 x 600 | 150 - 200 | 40 |

| PG- 30 / 30 | 520 x 750 | 5 / 5 | 2 / 2 | 750x750 | 250-300 | 60 |

.jpg)

Hopper Feed Grinder(HBG-series)

Heavy duty welded/machined steel construction

Cross cut body design maximized rotor dia and output for same chamber size compared to horizontal cut body grinders. It laso provide easy access in side chamber for ease of blade change and maintanance.

Outboard mounted plummer - block heavy duty spherical roller bearings with K-type aleeve to prevent contaminations entering the bearings ,and K-sleeve makes it is to remove bearings for easy maintanance.

Special design hopper attached to grinding chamber for enhanced cutting efficiency .Rotor and bed Knives are adjusted from outside of the granulator in the Precise Fixture/jig. constant cutting circle due to adjustable Knives.

| Model | Rotor Dia | Rotor Rows/ Blades | Fix Bed Rows/ Blades | Chamber Size | Output Kg/ Hr | Power HP |

|---|---|---|---|---|---|---|

| HBG-24/24 | 420 X 600 | 3/3 | 2/2 | 600 X 600 | 250-300 | 40 |

| HBG-24/48 | 420 X 1000 | 5/5 | 2/2 | 600 X 1000 | 400-450 | 60 |

| HBG-30/30 | 520 X 750 | 5/5 | 2/2 | 750 X 750 | 450-500 | 60 |

| HBG-30/60 | 520 X 1500 | 5/5 | 2/2 | 750 X 1500 | 650-750 | 90 |

| HBG-40/40 | 620 X 1000 | 5/5 | 2/2 | 750 X 1000 | 650-750 | 120 |

| HBG-40/60 | 620 X 1500 | 5/5 | 2/2 | 750 X 1500 | 1000-1200 | 150 |

.jpg)

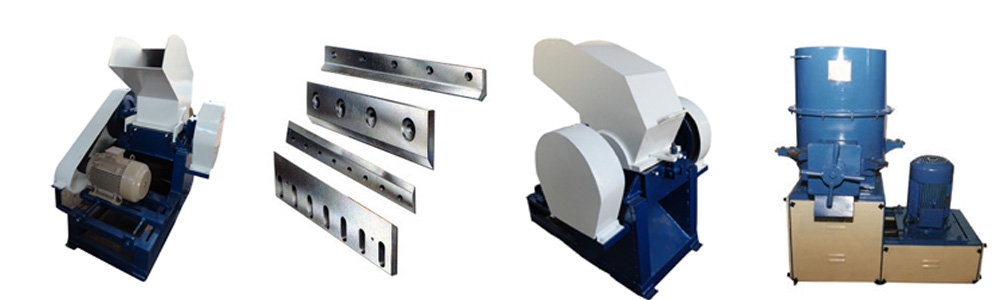

Heavy duty welded/machined steel construction.

Cross cut body design maximizes rotor dia and output for same chamber size compared to horizontal cut body grinders. It also provides easy access in side chamber for ease of blade change and maintenance.

Outboard mounted Plummer- block heavy duty spherical roller bearings with K-type sleeve to prevent contaminations entering the bearings, and K-sleeve makes it easy to remove bearings for easy maintenance.

Special design Screw Force feeder attached to grinding chamber for enhanced cutting efficiency.

Rotor and bed knives are adjusted from outside of the granulator in the Precise Fixture/Jig.

Constant cutting circle due to adjustable knives.

Force feeder Provides economical operation due to less power/MT cutting.

Very compact design.

Wear plates to protect the body.

Free hole in rotor and fix bed assembly with lock plate leaves no reason for maintenance.

Application:

Almost all type of plastic waste can be grinded in this type of machine.

Lumps ,Small plastic articles, Small Injection Molding waste, Films, Raffia, Low thickness Pipes etc.

| Model | Rotor dia x Length | Rotor rows/Blades | Fix Bed rows/Blades | Chamber size | Output Kg/ Hr. | Power HP |

|---|---|---|---|---|---|---|

| HBG-24/24 | 420x600 | 5/5 | 2/2 | 600x600 | 600-700 | 60 |

| HBG-24/48 | 420x1000 | 5/5 | 2/4 | 600x1000 | 800-1000 | 60 |

| HBG-30/30 | 520x750 | 5/5 | 2/2 | 750x750 | 800-900 | 90 |

| HBG-30/60 | 520x1500 | 5/5 | 2/6 | 750x1500 | 1200-1500 | 120 |

| HBG-40/40 | 620x1000 | 7/7 | 2/4 | 750x1000 | 1000-1200 | 120 |

| HBG-40/60 | 620x1500 | 7/7 | 2/6 | 750x1500 | 1500-1800 | 160 |

+91

+91